|

Bearing may refer to:

Non-circular gears are designed for special purposes. While a regular gear is optimized to transmit torque to another engaged member with minimum noise and wear and maximum efficiency, a non-circular gear’s main objective might be ratio variations, axle displacement oscillations and more. Common applications include textile machines, potentiometers and continuously variable transmissi This article is about mechanical gears. For other uses, see Gear (disambiguation).

Two meshing gears transmitting rotational motion. Note that the smaller gear is rotating faster. Although the larger gear is rotating less quickly, its torque is proportionally greater. The gears in a transmission are analogous to the wheels in a pulley. An advantage of gears is that the teeth of a gear prevent slipping. When two gears of unequal number of teeth are combined a mechanical advantage is produced, with both the rotational speeds and the torques of the two gears differing in a simple relationship. In transmissions which offer multiple gear ratios, such as bicycles and cars, the term gear, as in first gear, refers to a gear ratio rather than an actual physical gear. The term is used to describe similar devices even when gear ratio is continuous rather than discrete, or when the device does not actually contain any gears, as in a continuously variable transmission. The earliest known reference to gears was circa A.D. 50 by Hero of Alexandria, but they can be traced back to the Greek mechanics of the Alexandrian school in the 3 century B.C. and were greatly developed by the Greek polymath Archimedes (287–212 B.C.).The earliest known reference to gears was circa A.D. 50 by Hero of Alexandria, but they can be traced back to the Greek mechanics of the Alexandrian school in the 3 century B.C. and were greatly developed by the Greek polymath Archimedes (287–212 B.C.).

The automobile transmission allows selection between gears to give various mechanical advantages An external gear is one with the teeth formed on the outer surface of a cylinder or cone. Conversely, an internal gear is one with the teeth formed on the inner surface of a cylinder or cone. For bevel gears, an internal gear is one with the pitch angle exceeding 90 degrees. Internal gears do not cause direction reversal.

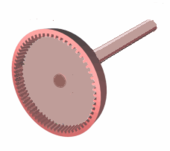

Spur gears or straight-cut gears are the simplest type of gear. They consist of a cylinder or disk with the teeth projecting radially, and although they are not straight-sided in form, the edge of each tooth is straight and aligned parallel to the axis of rotation. These gears can be meshed together correctly only if they are fitted to parallel axles

Helical gears offer a refinement over spur gears. The leading edges of the teeth are not parallel to the axis of rotation, but are set at an angle. Since the gear is curved, this angling causes the tooth shape to be a segment of a helix. Helical gears can be meshed in a parallel or crossed orientations. The former refers to when the shafts are parallel to each other; this is the most common orientation. In the latter, the shafts are non-parallel.

The angled teeth engage more gradually than do spur gear teeth causing them to run more smoothly and quietly. With parallel helical gears, each pair of teeth first make contact at a single point at one side of the gear wheel; a moving curve of contact then grows gradually across the tooth face to a maximum then recedes until the teeth break contact at a single point on the opposite side. In spur gears teeth suddenly meet at a line contact across their entire width causing stress and noise. Spur gears make a characteristic whine at high speeds and can not take as much torque as helical gears. Whereas spur gears are used for low speed applications and those situations where noise control is not a problem, the use of helical gears is indicated when the application involves high speeds, large power transmission, or where noise abatement is important. The speed is considered to be high when the pitch line velocity exceeds 25 m/s.A disadvantage of helical gears is a resultant thrust along the axis of the gear, which needs to be accommodated by appropriate thrust bearings, and a greater degree of sliding friction between the meshing teeth, often addressed with additives in the lubricant. For a crossed configuration the gears must have the same pressure angle and normal pitch, however the helix angle and handedness can be different. The relationship between the two shafts is actually defined by the helix angle(s) of the two shafts and the handedness, as defined:

Where β is the helix angle for the gear. The crossed configuration is less mechanically sound because there is only Main article: Double helical gear

Double helical gears, or herringbone gear, overcome the problem of axial thrust presented by "single" helical gears by having two sets of teeth that are set in a V shape. Each gear in a double helical gear can be thought of as two standard mirror image helical gears stacked. This cancels out the thrust since each half of the gear thrusts in the opposite direction. Double helical gears are more difficult to manufacture due to their more complicated shape. For each possible direction of rotation, there are two possible arrangements of two oppositely-oriented helical gears or gear faces. In one possible orientation, the helical gear faces are oriented so that the axial force generated by each is in the axial direction away from the center of the gear; this arrangement is unstable. In the second possible orientation, which is stable, the helical gear faces are oriented so that each axial force is toward the mid-line of the gear. In both arrangements, when the gears are aligned correctly, the total (or net) axial force on each gear is zero. If the gears become misaligned in the axial direction, the unstable arrangement generates a net force for disassembly of the gear train, while the stable arrangement generates a net corrective force. If the direction of rotation is reversed, the direction of the axial thrusts is reversed, a stable configuration becomes unstable, and vice versa. Stable double helical gears can be directly interchanged with spur gears without any need for different bearings. Main article: Bevel gear

A bevel gear is shaped like a right circular cone with most of its tip cut off. When two bevel gears mesh their imaginary vertices must occupy the same point. Their shaft axes also intersect at this point, forming an arbitrary non-straight angle between the shafts. The angle between the shafts can be anything except zero or 180 degrees. Bevel gears with equal numbers of teeth and shaft axes at 90 degrees are called miter gears. The teeth of a bevel gear may be straight-cut as with spur gears, or they may be cut in a variety of other shapes. Spiral bevel gear teeth are curved along the tooth’s length and set at an angle, analogously to the way helical gear teeth are set at an angle compared to spur gear teeth. Zerol bevel gears have teeth which are curved along their length, but not angled. Spiral bevel gears have the same advantages and disadvantages relative to their straight-cut cousins as helical gears do to spur gears. Straight bevel gears are generally used only at speeds below 5 m/s (1000 ft/min), or, for small gears, 1000 r.p.m. Main article: Spiral bevel gear

Hypoid gears resemble spiral bevel gears except the shaft axes do not intersect. The pitch surfaces appear conical but, to compensate for the offset shaft, are in fact hyperboloids of revolution. Hypoid gears are almost always designed to operate with shafts at 90 degrees. Depending on which side the shaft is offset to, relative to the angling of the teeth, contact between hypoid gear teeth may be even smoother and more gradual than with spiral bevel gear teeth. Also, the pinion can be designed with fewer teeth than a spiral bevel pinion, with the result that gear ratios of 60:1 and higher are feasible using a single set of hypoid gears. This style of gear is most commonly found in mechanical differentials. Crown gears or contrate gears are a particular form of bevel gear whose teeth project at right angles to the plane of the wheel; in their orientation the teeth resemble the points on a crown. A crown gear can only mesh accurately with another bevel gear, although crown gears are sometimes seen meshing with spur gears. A crown gear is also sometimes meshed with an escapement such as found in mechanical clocks. Main article: Worm drive

Worm gears resemble screws. A worm gear is usually meshed with an ordinary looking, disk-shaped gear, which is called the gear, wheel, or worm wheel. Worm-and-gear sets are a simple and compact way to achieve a high torque, low speed gear ratio. For example, helical gears are normally limited to gear ratios of less than 10:1 while worm-and-gear sets vary from 10:1 to 500:1. A disadvantage is the potential for considerable sliding action, leading to low efficiency. Worm gears can be considered a species of helical gear, but its helix angle is usually somewhat large (close to 90 degrees) and its body is usually fairly long in the axial direction; and it is these attributes which give it its screw like qualities. The distinction between a worm and a helical gear is made when at least one tooth persists for a full rotation around the helix. If this occurs, it is a ’worm’; if not, it is a ’helical gear’. A worm may have as few as one tooth. If that tooth persists for several turns around the helix, the worm will appear, superficially, to have more than one tooth, but what one in fact sees is the same tooth reappearing at intervals along the length of the worm. The usual screw nomenclature applies: a one-toothed worm is called single thread or single start; a worm with more than one tooth is called multiple thread or multiple start. The helix angle of a worm is not usually specified. Instead, the lead angle, which is equal to 90 degrees minus the helix angle, is given. In a worm-and-gear set, the worm can always drive the gear. However, if the gear attempts to drive the worm, it may or may not succeed. Particularly if the lead angle is small, the gear’s teeth may simply lock against the worm’s teeth, because the force component circumferential to the worm is not sufficient to overcome friction. Worm-and-gear sets that do lock are called self locking, which can be used to advantage, as for instance when it is desired to set the position of a mechanism by turning the worm and then have the mechanism hold that position. An example is the machine head found on some types of stringed instruments. If the gear in a worm-and-gear set is an ordinary helical gear only a single point of contact will be achieved. If medium to high power transmission is desired, the tooth shape of the gear is modified to achieve more intimate contact by making both gears partially envelop each other. This is done by making both concave and joining them at a saddle point; this is called a cone-drive. Worm gears can be right or left-handed following the long established practice for screw threads. Main article: Non-circular gear

Non-circular gears are designed for special purposes. While a regular gear is optimized to transmit torque to another engaged member with minimum noise and wear and maximum efficiency, a non-circular gear’s main objective might be ratio variations, axle displacement oscillations and more. Common applications include textile machines, potentiometers and continuously variable transmissions. From Wikipedia, the free encyclopedia : Manufacture of gears, bearings and other driving elements |